40 Key moments

1979

Company founded

"We felt there was room for a distributor offering a superlative service at reasonable prices", says Mike Lee, the co-founder of Rapid with Chris Stevenson. The original vision, according to Chris, was to offer a broad range of products via a catalogue to compete with the big names in the electronics business. But all big ambitions have to start somewhere small.

In July 1979 Mike and Chris rented a converted room above a garage in the village of Eynsford, near Dartford in Kent. "This was a very basic 300 sq foot store", says Chris. "We had no connection with the owner of the house, who used to leave our mail at the bottom of the stairs. The water in the kettle would regularly freeze!"

Chris Stevenson

Chris Stevenson

Mike Lee

Mike Lee

1980

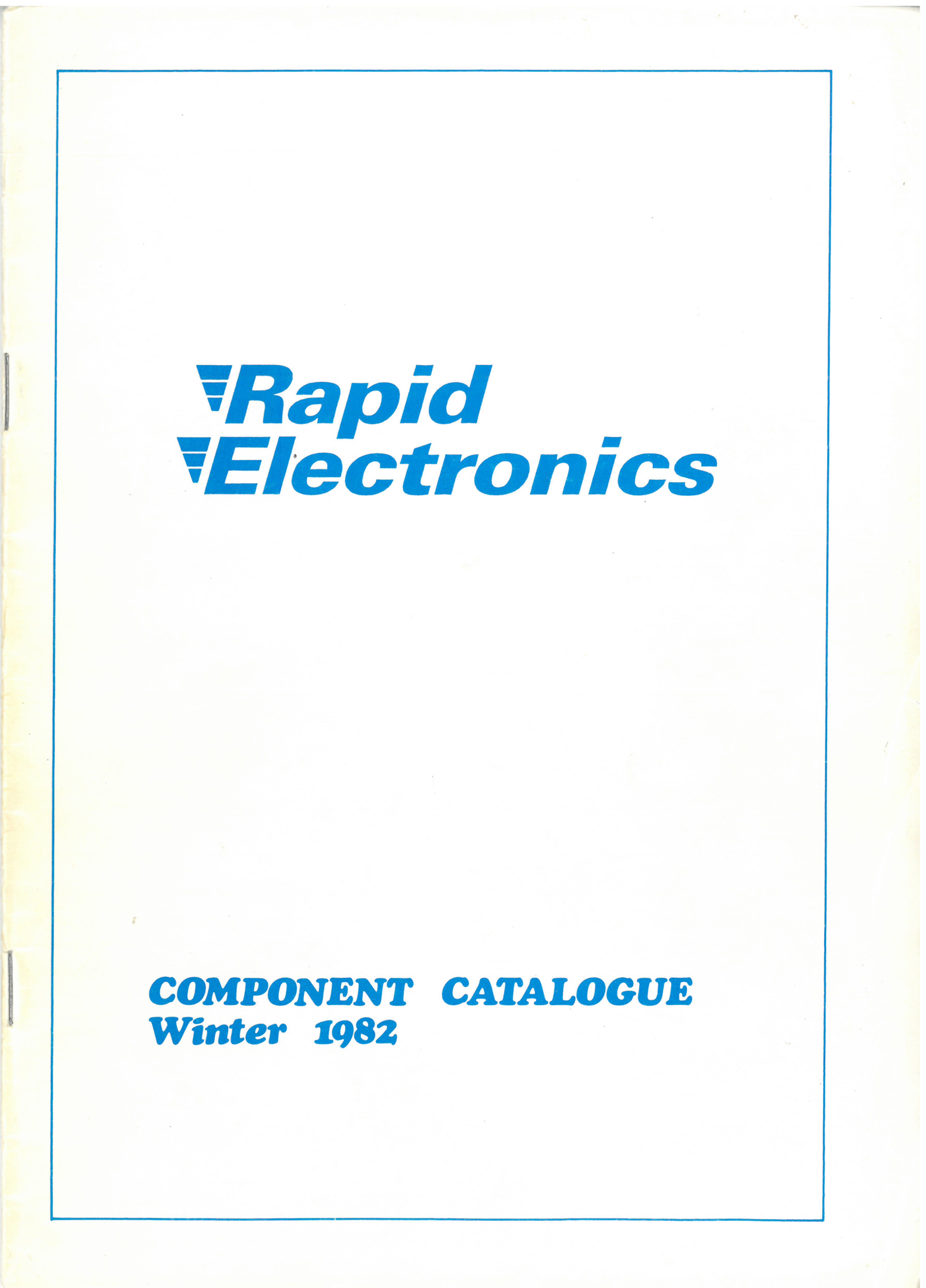

First catalogue printed

The business model for Rapid was as a mail order company. The first catalogue was posted to customers in 1980. The catalogue would remain the primary method of marketing for over 30 years. As the company’s product range grew, so did the catalogue. By the mid-2000s it was clocking in at a hefty 1,300 pages. The final industry catalogue was printed in 2011, as customers began to order more from the website. But old habits die hard and we still get asked if a catalogue is available!

1983

The green shed days

As the business grew, larger premises were required. Unable to find a site in Kent, Chris and Mike looked further afield. Mike’s parents lived in Long Melford in Suffolk, and it was Mike’s father John who introduced him to the manager of a nearby site on Hill Farm industrial estate in Boxted, on the outskirts of Colchester. So began what are affectionately known among long time employees as ‘the green shed days’.

1983

First full-time employee

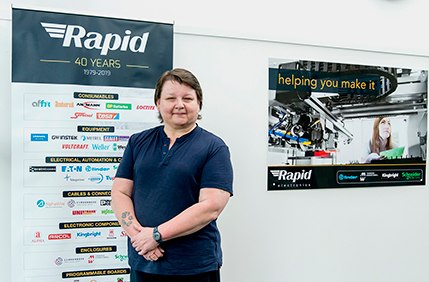

In these early years the work was done almost solely by Mike and Chris. It was not until September 1983 that Rapid took on its first full-time member of staff – Lynn Evans. Quite remarkably Lynn is still with the company, 36 years later.

Lynn joined Rapid a few months after leaving school after answering an ad in the local paper. “I lived in Boxted, so it was ideal for me. I went for an interview on a Friday with Mike Lee, and then he rang back and asked if I could start on the Monday. I was very nervous!” Lynn picked and packed orders, but it was a lot different in those ‘green shed days’: "We had no part numbering system – we literally had to work out what part the customer wanted from their own description of it, and learn it. You just had to hope you got it right and usually we did!"

"I did a bit of everything really – took orders over the phone, picked and packed, helped back the computer system up on floppy disk and used those old credit card swiping machines (I remember having to ring up the bank to get payments authorised). It’s all changed today, but every day was different."

"I’ve never thought about leaving", says Lynn. "I’ve grown up with the company and there’s been so many people who’ve done the same – there has always been a family feel to Rapid. I’m very proud to be our longest serving employee!"

Lynn at work (left) in the 1990s

Lynn at work (left) in the 1990s

Lynn today

Lynn today

1985

Founding of International Purchasing Office

Mike Lee has always said that the founding of Rapid’s International Purchasing Office in Taiwan was one of the most significant events in the company’s history. Chris Stevenson agrees. “It gave us an opportunity to source direct from our Taiwanese suppliers and establish good working relationships.” Susan Wang, Mike Lee’s sister-in-law, looked after operations in Taipei. A network of over 50 suppliers was developed, including with leading manufacturers like Kingbright with whom Rapid is still a close partner.

1985

Move to larger site in Boxted

Within a few years the company had outgrown the original buildings they occupied at Hill Farm. The large deliveries now coming in from the Far East meant that the ‘green shed days’ were numbered. Rapid bought a larger site nearby on the same estate and found the base they needed to expand.

"Making the best use of the available space at Boxted was always tight," Chris Stevenson remembers, "as well as persuading potential staff that Boxted was not that far to travel to!” There were challenges that no business management course could really prepare a boss for, like the Great Storm of 1987. “The Monday morning after the storm we arrived to find the entire warehouse under a foot of water. The staff pulled together and used hair dryers to salvage the products!"

Here are some of the staff pictured in 1988: from left to right, standing - Chentza Lee, Mike Lee, John Lee, Lynn Evans, Pat Beck, Lesley Graves, Chris Stevenson, Susan Wang, sitting – Sue Harris, Anita Cole.

Here are some of the staff pictured in 1988: from left to right, standing - Chentza Lee, Mike Lee, John Lee, Lynn Evans, Pat Beck, Lesley Graves, Chris Stevenson, Susan Wang, sitting – Sue Harris, Anita Cole.

1985

Denise Bird joins

Denise Bird is another of Rapid’s long-time employees. Joining the company in January 1985 as a Sales clerk – she still has the office stamp she was given on her first day! – Denise has worked in a variety of roles, including Admin manager, IT Manager and her current role as HR manager.

Denise has done and seen pretty much everything Rapid life has to offer – picked and packed orders, laid IT cables, bought computer systems, mopped up the warehouse (see above) – but has loved every minute of it. “It’s been my life, my passion, and I feel lucky to have been on the journey and seen the company grow. As a small team we pulled together and did all we could to make sure orders went out, whatever the circumstances. We may be a little bit bigger now but the principles are still the same – the customer has always come first.”

As HR manager Denise has created initiatives like the Wellbeing and Core Values programme, which looks after aspects of employees’ physical and mental health. It is the kind of scheme that just would not have been possible in 1985. “Financially we always ran a tight ship but that enabled the company to grow. We are reaping the benefits now and I am proud of the culture we have been able to develop for our staff.”

Denise on her 10th anniversary presentation

Denise on her 10th anniversary presentation

Denise today

Denise today

1989

First purpose-built site

The late 1980s were a period of considerable growth for the company. The pressure of rising inventory levels and accommodating administrative staff meant that larger premises were needed. Land was purchased in Heckworth Close in the Severalls Industrial Estate in the north of Colchester, around three miles away from Boxted. This was a far better location, closer to other businesses and offering room for expansion. The site was built to Rapid’s specification. A mezzanine floor was added a few years later.

1995

Extension built at Heckworth Close

"A new warehouse was needed to handle the increased order volumes", recalls Chris Stevenson. "We also wanted to improve the order flow through the warehouse through the introduction of zoned picking and conveyor systems." The company bought a vacant lot across the road to house the bulk stocks that were regularly arriving from China. The original site housed the picking areas.

Here is one of Rapid’s longest serving members of staff, Sue Harris, pictured in the expanded premises.

1998

Installed CSD computer system

Rapid have been through a few computer systems in its time. Denise Bird remembers a visit to Dixons with Chris Stevenson to buy a 20MB PC. “We thought it was the bees’ knees!” There were a few painful experiments with companies like Kerridge and Cyberaid, but many current employees will remember CSD, which powered the company for around 10 years, well into the new millennium. It had a few foibles, and was known to freeze from time to time, giving rise to the infamous cry around the office of ‘BACK TO BASE DATA!!’

Denise and Chris, at Heckworth Close in the 1990s

Denise and Chris, at Heckworth Close in the 1990s

1999

First full colour catalogue

Rapid’s product catalogue was originally produced by an external company, Stibo, with all product photographs in black and white.

Rapid’s first full-colour catalogue also saw it being produced in-house for the first time. John Blanchard, then a product manager and still one of the company’s technical authors, worked on the project. “A small team beavered away in the so-called ‘Wendy House’ on the mezzanine floor in Rapid’s old building in Heckworth Close, transferring text from Stibo’s system to the new 4D catalogue software, as well as arranging the photography of hundreds of products where the image was still in black-and-white.”

“The process didn’t go without its share of problems and software glitches, but eventually, a catalogue was produced and sent off to the printer. The catalogue was well received by staff and customers alike, setting the standard for future catalogues and providing another milestone along the road of Rapid’s progress.”

John Blanchard, 2nd from left (standing), with the Catalogue Production team in 2000.

John Blanchard, 2nd from left (standing), with the Catalogue Production team in 2000.

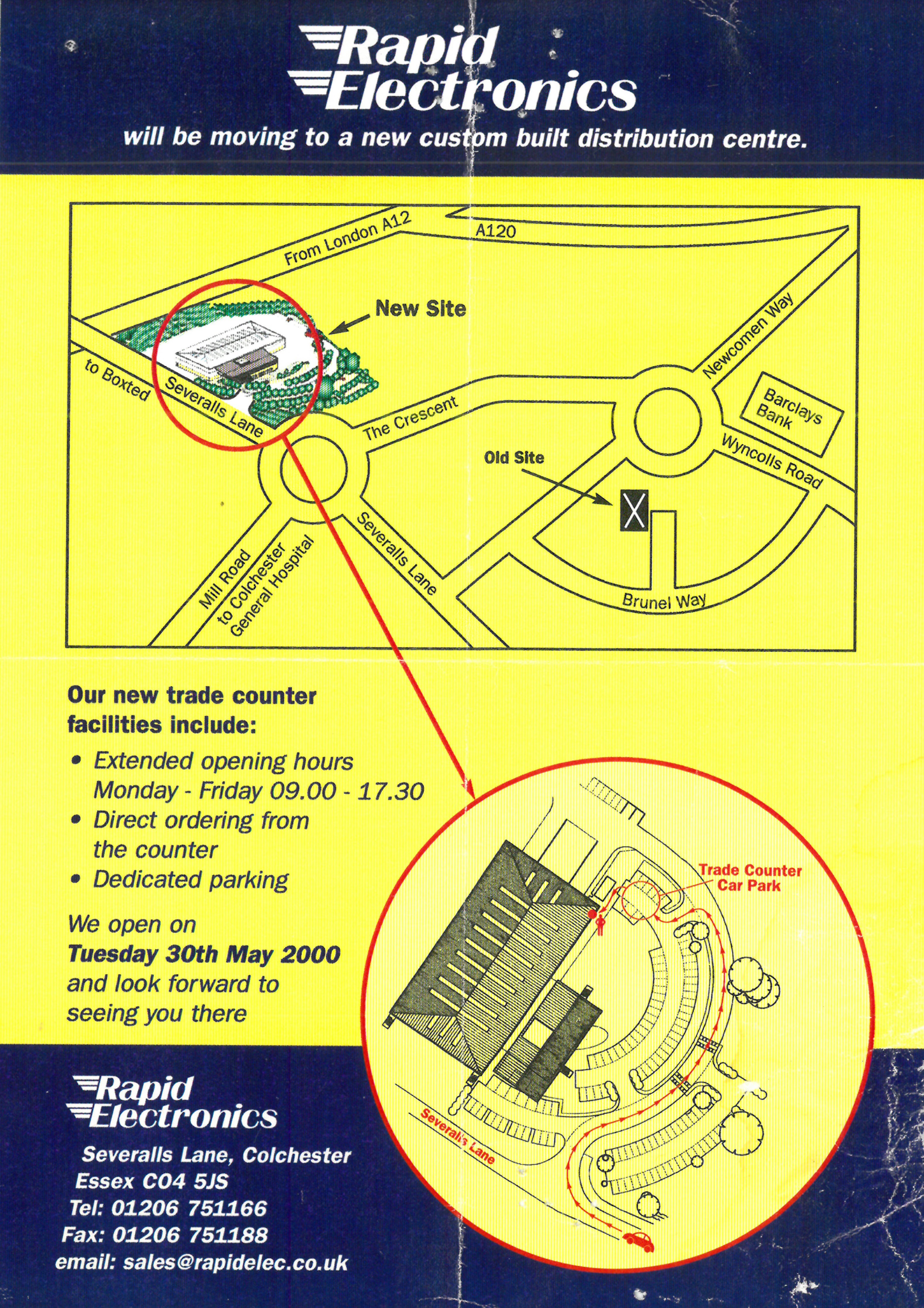

2000

Moved to current site

After a decade on the Heckworth Close site in Colchester Business Park, Rapid’s directors purchased a 110,000 sq ft site at Severalls Hall, around ½ mile away. Construction of the purpose-built distribution centre and offices began in 1999 and opened on 30th May 2000.

Speaking to a local newspaper at the time, Chris Stevenson said that the move would enable the company’s expansion and the provision of new automated packing, handling and storage facilities. ‘This represents a major step forward for Rapid’, he said. A significant innovation was the installation of a conveyor belt in the main warehouse, increasing the speed at which orders could be picked, packed and despatched.

2001

First education catalogue

Rapid had received orders from schools, colleges and universities from the company’s very earliest years, but it was not until 2001 that a separate education catalogue was produced, with a greater focus on products relevant to education buyers. It proved popular, and a full 1200-page education catalogue continued to be published until 2017, several years after the last industry catalogue. Smaller publications dedicated to products for specific subjects are still published, alongside a 300-page annual mini education catalogue.

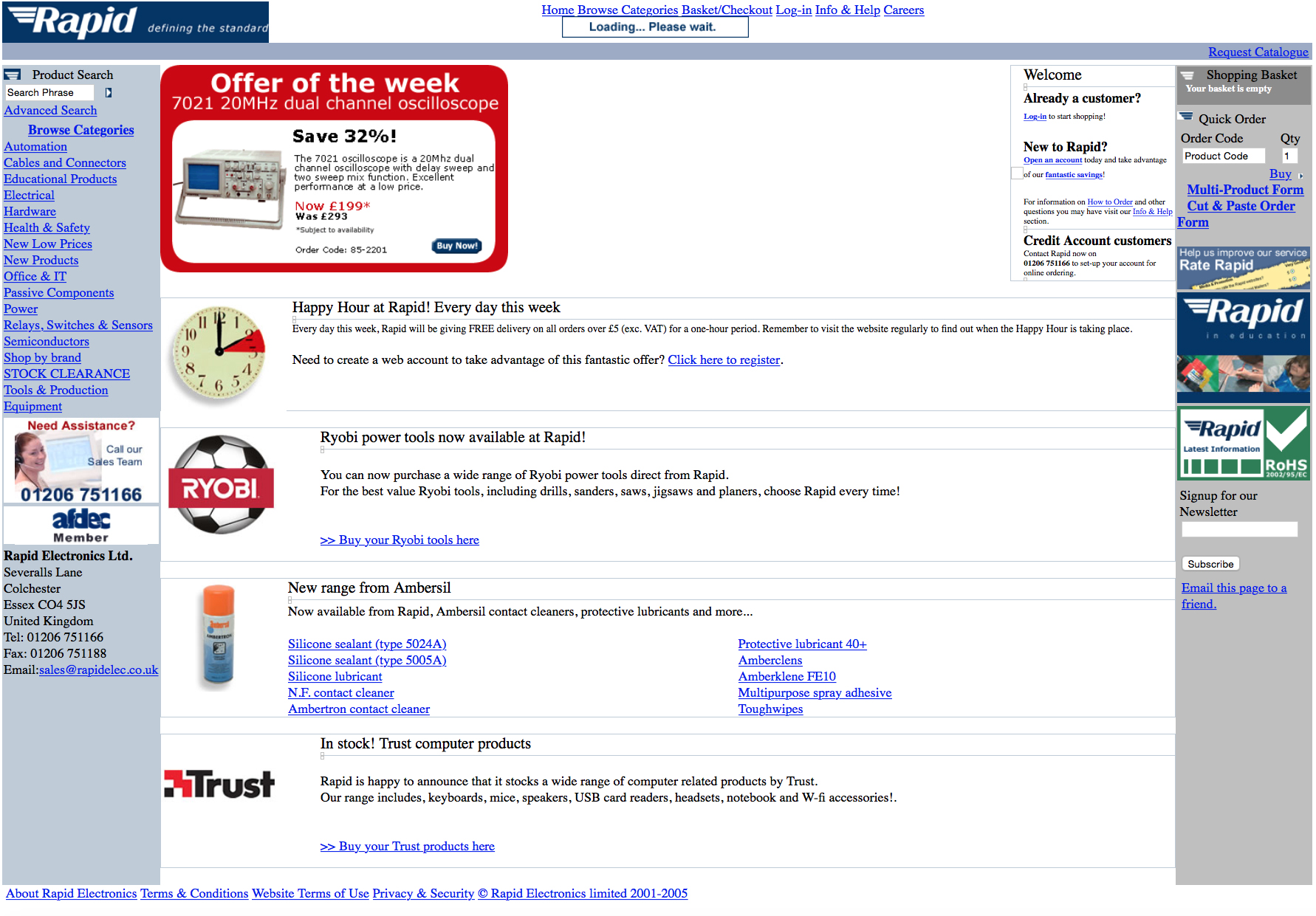

2002

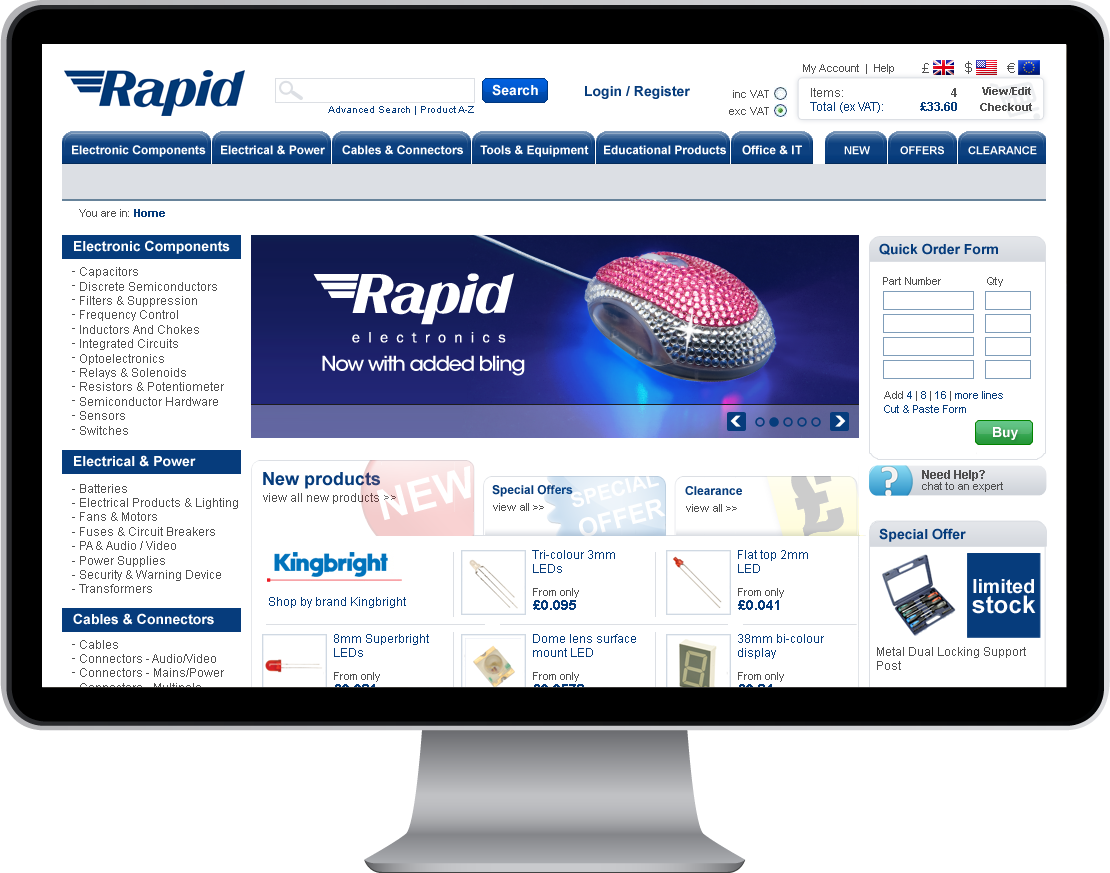

First website launched

It had been a long time coming, but Rapid finally went online in 2002. The original domain was www.rapidelec.co.uk. Two years later came www.rapidelectronics.co.uk. In 2006 the site was relaunched again as an e-commerce site, www.rapidonline.com, giving customers the opportunity to browse and buy products online.

Russell Morling was Rapid’s Web manager throughout this period.

“The first proper site was time-consuming to build (thank you Dreamweaver!), but a lot of fun at the same time”, says Russell. “Full e-commerce functionality arrived in 2006. Connecting to the existing product database and sales system proved taxing, but the end result was worth the long hours. It was great to see ‘my baby’ develop into the fully functional site that it is today, and I’m immensely proud of our efforts back in those early internet days!”

2003

‘Defining the Standard’ branding

The company ran an internal competition to devise a slogan or motto that could be used to promote Rapid. A member of the warehouse team came up with the winner – ‘Defining the Standard’. This was used on catalogues, letterheads, packaging, merchandise and marketing material until the ‘Helping you make it’ rebranding in 2017.

2004

Established Toyota Technology Challenge

Rapid has always been a keen supporter of educational initiatives, particularly those which promote electronics and skills that can be used in engineering careers. This major partnership with Toyota was a national educational competition for students aged from 11-16. The challenge tested students’ abilities to build and program environmentally friendly electric model vehicles using a PIC microcontroller and solar power. The National Finals were held at Toyota’s manufacturing plant in Derby. The challenge ran until 2013 and at its height 11,000 students took part.

2007

Trade Counter moved to present site

Even at the sites in Boxted there had been the facility for customers to call ahead and collect their order or have it picked while they waited. But there was not an official trade counter until the move to the current site in Severalls Lane. Originally this was sited in the main warehouse building, and in 2007 the Trade Counter moved to its present location, which had previously been used as office space. With the capacity to display 2,000 products, the Trade Counter is open six days a week to the general public as well as the trade.

2007

Awarded ERA Supplier of the Year

Rapid’s commitment to the Education sector was recognised in 2007 when the company won Supplier of the Year for companies with over £3million annual turnover at the Education Resources Awards. These awards were presented by BESA, the British Educational Suppliers Association. This was a major coup for Rapid, with the company in competition with specialist educational suppliers. Kate Rushworth, Rapid’s Education manager at the time, said: “We were very proud of the range of our educational products and the quality of our service to schools, colleges and universities.”

2008

Debut on social media

Rapid went live on Facebook in June 2008. Twitter followed soon afterwards, and it wasn’t long before social media was playing an important part in the company’s communications and public profile. LinkedIn, YouTube and Instagram have also proved popular in reaching different audiences, engaging with customers and suppliers and giving an insight into what goes on behind the scenes at the company.

2008

AFDEC Marketing Award

The company was recognised for the quality of its direct marketing from AFDEC (the Association of Franchised Distributors of Electronic Components) in its 2008 Marketing Awards. The Design and Manufacture publication won ‘Best Product Promotional Advertising – Print Format’, beating entries from competitors across the electronics industry.

2008

Car parking for Colchester Utd FC

Rapid has always had a good relationship with its closest Football League club, Colchester United, from advertising at its old Layer Road ground to players opening the Trade Counter. When the club’s new stadium opened in 2008, around a mile from Rapid’s distribution centre and offices, the company started offering supporters the chance to park their cars on its premises on match days in return for a small fee. The sums of money raised from this service are donated to a number of local charities, including St Helena Hospice.

2011

New website launched

A major project to build a completely new Rapid website went live in August 2011. The new site, although retaining the previous URL, www.rapidonline.com, came with a completely new look, navigation, faster search and interactive features. Much of the new functionality, such as accessing invoices online, order tracking and product questions, have remained key features of the site. "The changes we have made are more than just cosmetic; the site looks fantastic, but it is also quicker, more powerful and easier to use", said the company’s then Chief Operating Officer Ron McConnachie.

2012

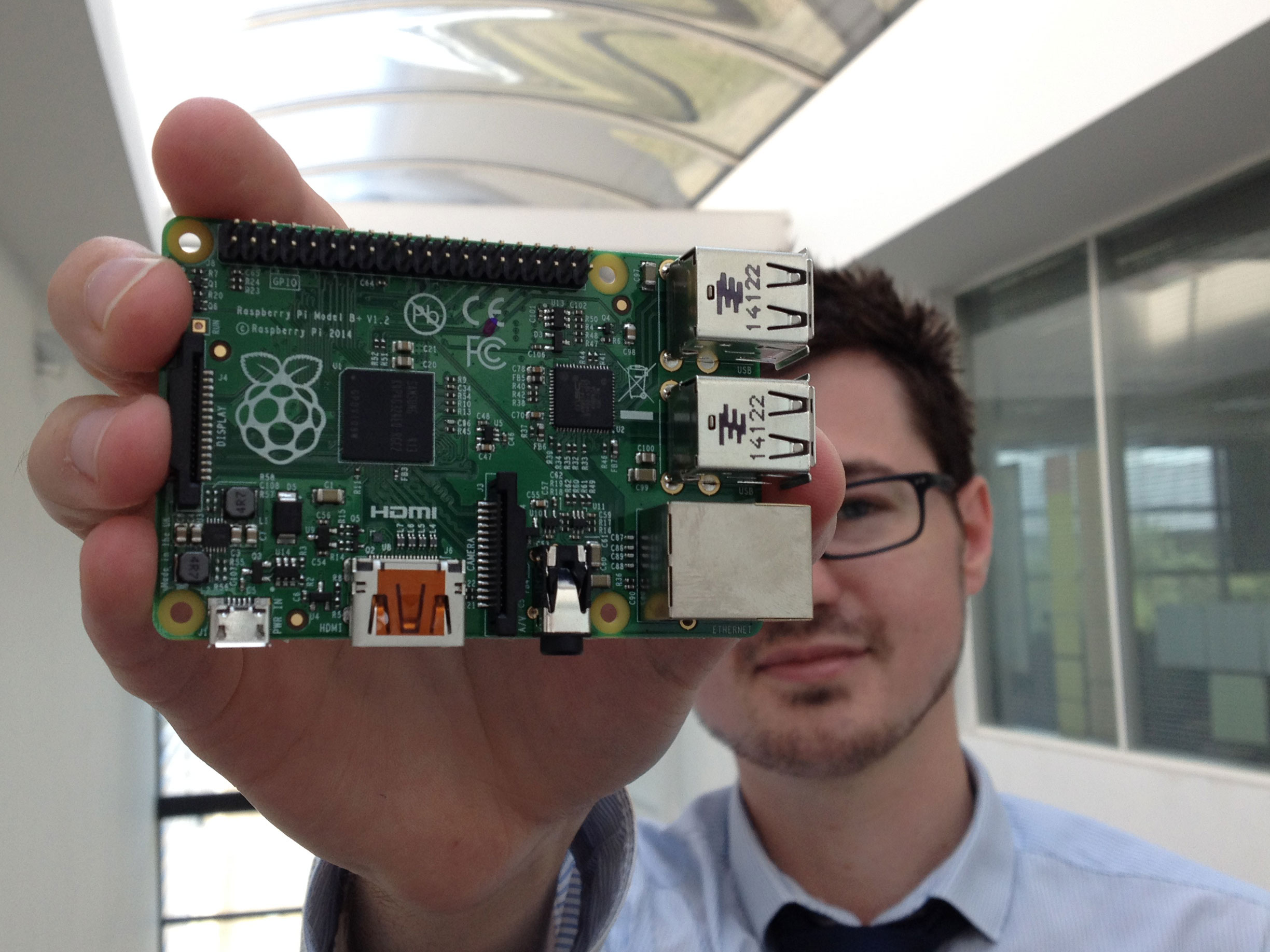

Started selling Raspberry Pi

Where were you when you first heard about the Raspberry Pi?

Rapid had always offered kits and chips that helped people of all ages learn about coding, prototyping and programming, but when the Pi was released in early 2012, coding went mainstream. Rapid has embraced the maker movement in all its many hardware manifestations, including Arduino, BBC micro:bit, Adafruit and other IoT platforms. The company even helped to develop the Arduino-compatible Orangepip board, and has also sponsored Raspberry Pi Jams and Pi Wars robotics teams.

2012

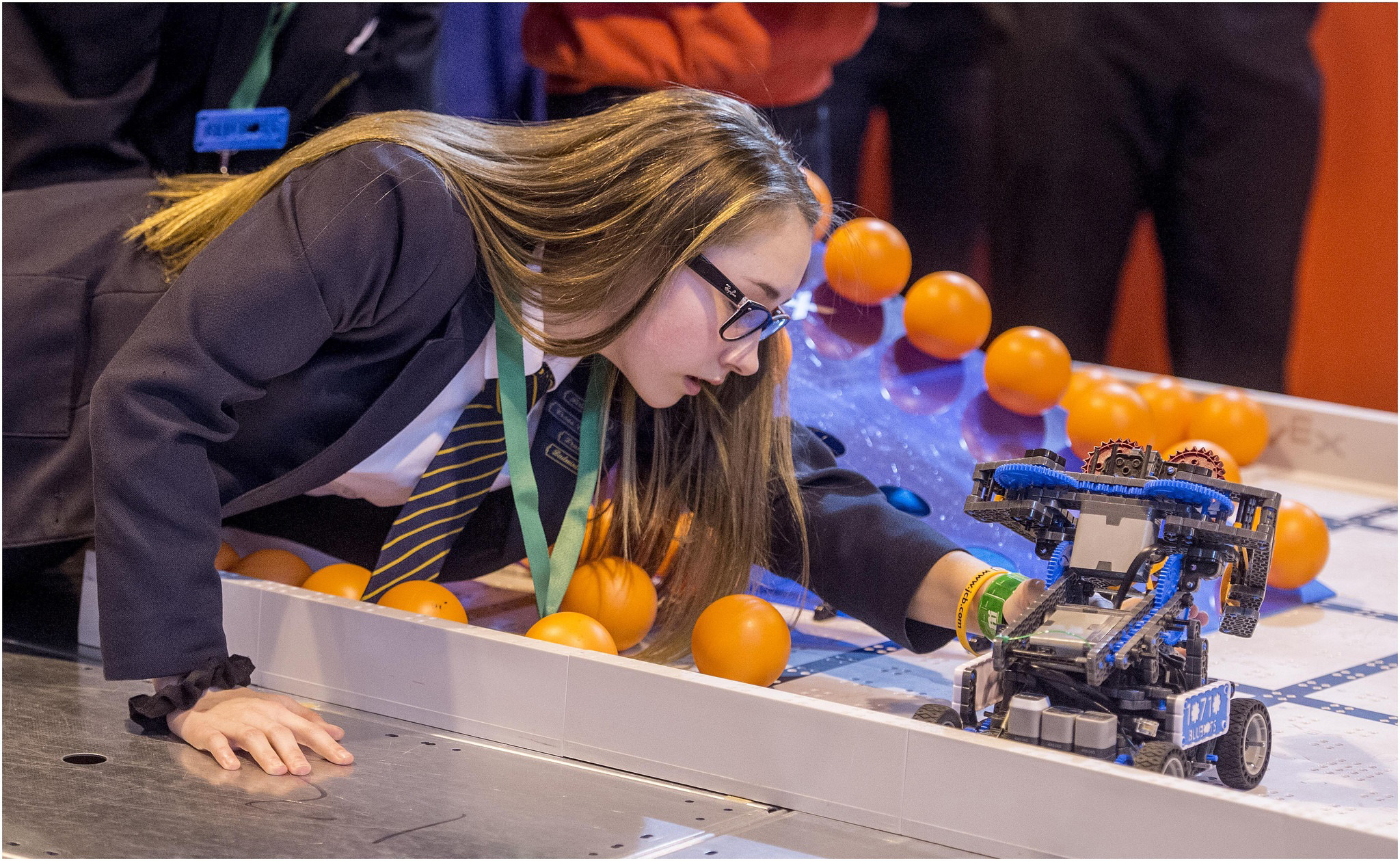

Began partnership with VEX Robotics

Since 2012 Rapid has been a key partner with VEX Robotics in promoting the VEX EDR and VEX IQ platforms, which gives students aged 8-18 the chance to design, build and program competitive level robots. Schools compete at regional and national events, with the ultimate aim of reaching the World Championships, held every year in the US. Rapid’s Education Manager Chris Calver was an inspirational mentor to many schools, guiding teams from their very first taster sessions to competing at international level with distinction.

“Finding the right partner to achieve success in supporting schools and teachers across the UK was critical for the growth of the VEX Robotics platform - but in particular for the extra-curricular VEX Robotics Competition programmes,” says Paul McKnight, Head of Operations, VEX Robotics (Europe).

“Rapid have been able to support our aims in making VEX Robotics accessible to schools and colleges, from primary right through to universities”, according to Paul. “Holding stock of the product, a comprehensive web presence, expert technical support and support at regional and national events – Rapid are not just a reseller, they are a true partner at every level. Their staff work with ours to ensure shared success. We couldn't ask more from them and look forward to many more years of working together!”

2012

James Bell appointed Managing Director

After two years as Rapid’s Sales Director, James Bell became Managing Director in 2012. This was a critical moment for the company, with one of James’s first tasks managing the transition to the Conrad Group. James liaised closely with senior management in Conrad’s Austrian and German headquarters to develop mutual understanding, shared goals and synergies between the two companies. James’s links with Rapid continue to the present day, as he now works in a managerial position in the Conrad Group.

2013

Joins the Conrad Group

After nearly 34 years as an independent company, Rapid took the decision to join the Conrad Group, one of Europe’s most successful mail order and web-based electronics retailers. James Bell said at the time: “Becoming part of the Conrad group is an incredible opportunity for everyone at Rapid Electronics. We are proud to have been an independent distributor for over 30 years, but this gives us the security and ability to grow in the years to come.” It has been a rewarding partnership which has enabled the company to make significant additions and improvements to its product range and operations.

2013

Awarded NUWPEC tender for electronic components & service aids

Rapid’s successful bid for this educational tender underlined its status as a preferred supplier to universities. Six regional purchasing councils make up the National Universities Working Party on Electronic Components, and the consortia work together with framework agreements to offer its members access to the highest quality products at the most competitive prices. Rapid has since been awarded all three remaining Lots in the current framework agreement, covering Tools and Fixings, Test & Measurement Equipment and Batteries.

2013

Launched mobile website

The way customers were buying from Rapid was changing. In 2013 10% of the company’s website traffic came from smartphones and tablets, so developing a site that was optimised for mobile devices became essential. The site – m.rapidonline.com – adapted to the screen size of particular devices, offered a quick search facility and simplified category navigation. It was an important stage in the evolution of Rapid’s online presence, which would eventually see a fully responsive single website launched in 2018.

2014

100,000 products available for the first time

The milestone of becoming a six-figure supplier arrived in September 2014. This target was reached due to a period of significant growth for the company. After becoming part of the Conrad Group, Rapid vastly expanded its electronic, electrical and e-mech ranges, signing distribution agreements with major suppliers such as WAGO. Rapid worked closely with its European partner to increase its product offering without putting a strain on the physical capacity of its distribution centre. Many products were available to order from Rapid and despatched from Conrad’s European warehouse.

2014

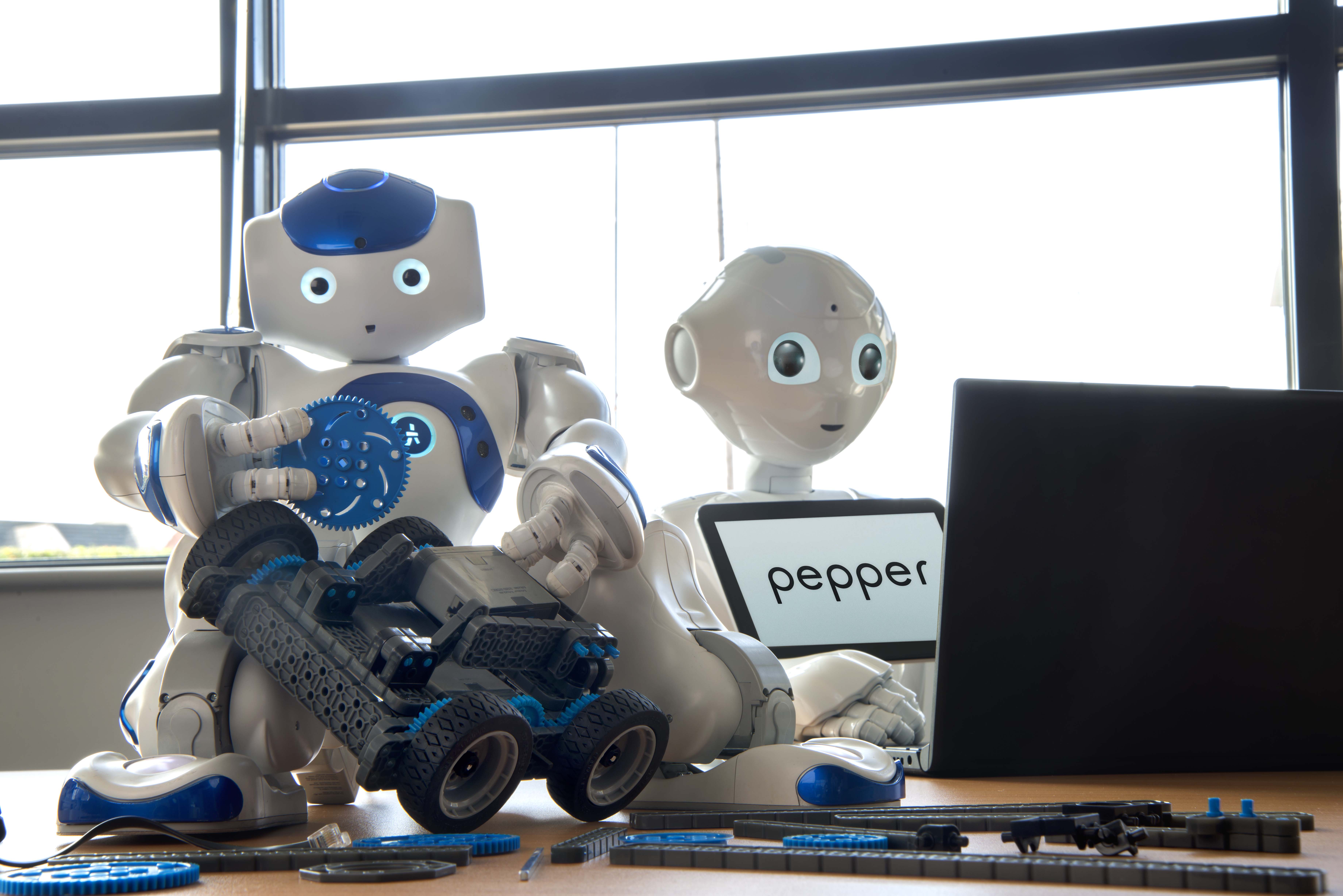

Started selling humanoid robots

First there was NAO, a charming 58cm tall robot who could engage in conversation, pick himself up and – perhaps most memorably – dance Gangnam Style on live TV. Then a couple of years later came Pepper – a 1.2m high autonomous talking humanoid robot programmed to perceive human emotions. Both marked major developments in how robots could be used as part of educational robotics and integrated in areas such as programming, systems and control and computer sciences.

2015 & 2017

Shortlisted for Elektra Distributor of the Year

The Elektra Awards are very much the Oscars of the electronics industry, and it was a major achievement for Rapid to be shortlisted twice in three years for the prestigious ‘Distributor of the Year’ category. In 2017 the company were also nominated at the Elektras for the ‘Educational Support Award’ for its work promoting STEM. At the time Managing Director James Bates said: “To be recognised in this way shows that we are making great progress as a company and offering services customers and suppliers value.”

2015

Introduced punchout services for universities

With much of university purchasing being undertaken via eProcurement ‘punchout’ systems, it was important for Rapid to become fully integrated with the most frequently used punchout platforms. These include Advanced (Science Warehouse), Proactis, CloudBuy, Jaggaer and Procserve. Buyers through these platforms are able to obtain access to national, regional and consortia pricing contracts, get framework agreement pricing and e-invoicing.

2016

James Bates appointed Managing Director

Rapid’s current MD was appointed in the summer of 2016. “I was delighted to be given the opportunity to lead a company like Rapid,” said James. “It has been a challenging period, but a hugely rewarding one. We have introduced some major new services that have made customers’ lives easier, built great partnerships with suppliers and are leading the way with innovations like turn-key solutions for EV charging. We are building a bright future for customers and employees.”

2017

Bespoke modification services launched

From enclosure modification to re-reeling, a number of bespoke services have been introduced to add value to core product ranges. Customers are now offered the opportunity to specify modifications such as cut-outs and paint colours to Hammond and CamdenBoss enclosures, as well as creating a bespoke cable assembly from the cable and connector of their choice. All such services are designed to streamline the number of suppliers a customer has to deal with and reduce the time involved in making their product ready for application.

2017

Started selling Loctite

Customers have been stuck on Loctite from the moment the company became a direct supplier of the adhesive in 2017. Why has it become one of our bestselling brands? Perhaps because Loctite is so versatile, the fact that it can be used for the most demanding of industrial applications as well as everyday tasks around the house. For example, Loctite threadlocker has been used to secure the gigantic boring machines that have dug London’s Crossrail tunnels. Rapid’s Loctite range covers the full selection of adhesive and sealants – from superglue to structural bonding, gasketing sealant to cyanoacrylate.

2017

Rebranded to ‘Helping you make it’

One of the first major internal processes that James Bates inaugurated was a review of what Rapid stood for, what it was good at and what it meant to its customers. The result was a complete rebranding of the company identity. “We realised that Rapid was dedicated to ‘helping you make it’,” says James. “That could be a simple home-made electronics project or a mass-produced circuit board for a contract manufacturer – the important thing is that we supply customers with the components, consumables and equipment required to design, manufacture and service high quality products.”

2017

Charitable donations pass £50,000 figure

Rapid has raised over £50,000 for various charities. The company’s fundraising activity has included assisting the Royal British Legion to sell poppies at Colchester’s largest supermarket since 2011, raising £1,027 for Comic Relief in 2017, and £716 for St Helena Hospice’s Midnight Walk in 2018. Charity donations are also generated from other initiatives such as dress down days and in-house staff events. Rapid also makes donations of products to charitable enterprises, such as assisting volunteers with educational projects in developing countries.

2018

Launched Airgineers

A new STEM enterprise for secondary schools, ‘Airgineers’, based on drone technology, was launched in 2018. Chris Calver, Rapid’s education manager, devised the challenge to fill a gap that he felt existed in the curriculum.

“Drone racing, in a safe environment, is pretty exciting as an educational challenge, and is a great way to engage students. But it is also incredibly rich in STEM learning opportunities. Students get involved in 3D printing and CAD design, learn how to build their drone and understand how to fly it using configuration software.”

2018

Achieved BSI ISO9001:2015 certification

A renewed focus on quality standards resulted in the company achieving a score of 100% on transition from ISO 9001 to the ISO 9001:2015 standard. As MD James Bates said: “This represents a fantastic achievement by everyone in the company. ISO 9001:2015 is a very high bar for any organisation, and means that our internal procedures, from risk assessment to regulatory compliance, meet the world’s most recognised QMS.”

2019

Replenishh EV brand launched

Rapid first entered the EV charging market in 2017, motivated by a desire to build the UK charging infrastructure in readiness for the huge anticipated increase in plug-in vehicles. We partnered with Schneider Electric and EO Charging to offer commercial and domestic customers a turn-key installation service via a network of trained installers. In 2019, our EV charging service was relaunched as Replenishh. Jim Rugg, Rapid’s EV Technical and Specifications Manager, said: “We want Replenishh to become the EV installers choice – a one-stop shop to order their charging hardware, design a project, book specialised training, integrate with the OLEV grant scheme and receive leads for potential customers.”